Have you ever wondered what helps an airplane stay together while traveling at high speeds? There is a world of technology that goes into making today’s fastest jets, and it just keeps getting better. Let’s take a closer look at some factors of why airplanes are riveted instead of welded.

Table of Contents

Why are airplanes riveted instead of welded ?

There are a few key reasons why rivets are used instead of welds for airplane production. The first reason would be that rivets points are stronger than weld points. Let’s go deeper into the subject.

Because most modern-day airplanes are made from aluminum, a weld isn’t the best bonding option between to pieces because when aluminum is heated up it becomes weak. Another key reason that engineers like to use rivets instead of welds is that rivet points are easier to inspect than weld points.

Weld Strength vs. Rivet Strength on Aluminum

Can you weld two pieces of aluminum together? Of course, you can with a TIG welder. But let it be noted that to make a good weld from two pieces of aluminum takes a decent amount of skill.

In production terms drilling a hole and inserting a rivet is much easier on a level of mass production. Rivets are much easier to do a quick scan with the eyes and inspect for perfection, and there is also less margin of error.

What Is a Rivet?

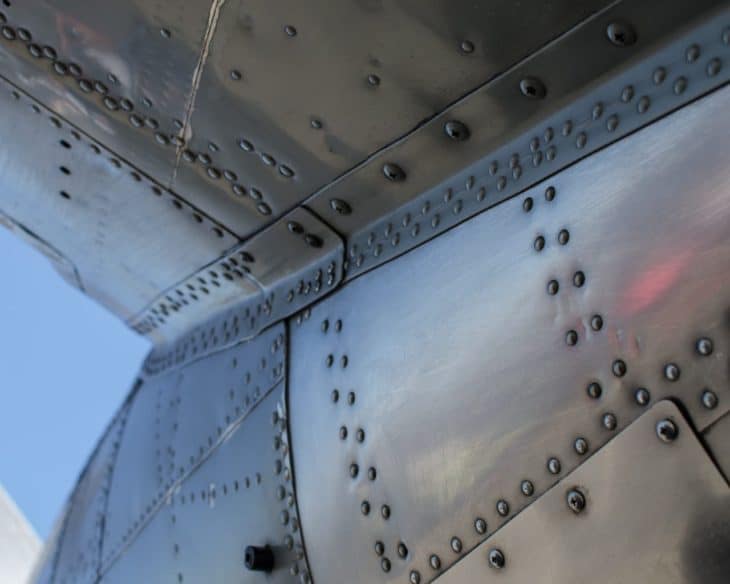

A rivet is a metal pin that is placed in between two matched holes and then upset by either a handtool or pneumatic rivet gun that expands the pin and creates a uniform head that sits smoothly on the surface.

The first step in installing a rivet is first drilling a hole in each part of the metal to allow for pin placement.

Specs of an Aircraft Grade Rivet

Just like all other components of an aircraft, the rivets that are used must be manufactured according to spec to ensure they can hold up to the load. Common rivets used include:

- 5056

- 2117-T

- 2024-T

- 2017-T

- 1100

These are five grades of rivets that are readily available and capable of being used on aircraft. They are usually made from an aluminum alloy just like the body of the airplane; mild steel rivets are also used to join steel parts on the airplane, as well as the 5056 rivets that are made from magnesium alloy that is resistant to corrosion.

Copper rivets can only be used on less significant materials like leather or parts that are made from copper alloys.

Why Not Use Screws for Assembling Aircraft?

So why not screws instead of rivets? The most important reason for using rivets instead of screws is because rivets can withstand vibration much better. Think about it; when a rivet is installed it expands to fill the hole.

When a screw is installed it turned by its head and grips to the sides of the metal with its threads, that can easily come loose with constant vibration at high speeds. Rivets are also significantly lighter than screws, making them the perfect option in aircraft assembly.

Why not Carbon Fiber?

The use of carbon fiber is another important subject to note when discussing aircraft production. With the discovery of nanotubes and a constantly growing quality in the use of composite materials, aircraft manufacturers are starting to rely more and more on carbon fiber to give additional strength to the design while conserving weight.

Carbon fiber is five times stronger than steel and barely even weighs half as much. Modern-day airplanes like the Boeing Dreamliner are made with 50% composite materials. Everything from body parts to propellers is made from this extremely futuristic material that is revolutionizing the way the world flies.

Can you put rivets into carbon fiber?

Technically yes you can, but it complicates things just a bit. Instead of using aluminum rivets it is necessary to use titanium because of the way aluminum weakens inside the carbon fiber.

Also, drilling holes in carbon fiber can create a weak point, so the thickness has to double to compensate for the perforations made. The technology of airplane manufacturing is something that is changing constantly.

References ▾

Related Posts